When you’re running large scale solar projects, whether it is a rooftop installation on an industrial building in Dubai, a utility farm in Iraq, the choice of solar panel technology is not just academic. For decision makers, JA Solar monocrystalline vs polycrystalline panels isn’t a trivial choice: it directly affects efficiency, return on investment, logistics, and long-term reliability.

In high stakes environments where you buy in containers, negotiate with customs, and care deeply about warranty, every percentage point of efficiency and every year of lifespan counts. This article talks about the technical characteristics, operational behavior, financial effect of JA Solar’s monocrystalline and polycrystalline panels,and polycrystalline panels, focusing on the priorities of a large scale, high volume purchaser like Pas Solar’s clients.

If you’re choosing the right option for your project, a trusted solar panel supplier Dubai can help you compare both technologies based on budget, climate, and required energy output.

This article explains the difference between monocrystalline and polycrystalline solar panels, focusing on JA Solar products.

| Feature / Factor | JA Solar Monocrystalline (Mono PERC) | JA Solar Polycrystalline |

|---|---|---|

| Efficiency Range | 20–23% | 15–18% |

| High Temperature Performance | Less efficiency loss in heat | More sensitive to heat, larger drop in hot climates |

| Low-Light Performance | Excellent (morning, evening, cloudy days) | Moderate, lower output in low-light conditions |

| Annual Degradation Rate | ~0.45% | 0.55–0.6% |

| Product Warranty | 12–15 years | 10–12 years |

| Performance Warranty | 25–30 years | Up to 25 years |

| Power Density | Higher, fewer panels needed | Medium, more panels required |

| Ideal Climate | Hot regions, strong sunlight | Mild to moderate climates |

| Upfront Cost | Higher | Lower |

| LCOE (Cost per kWh) | Lower in the long term | Potentially higher over time |

| Best Project Use | Industrial, commercial rooftops, residential with limited space, high ROI projects | Budget-limited projects, government tenders, high-volume contracts |

| Key Advantages | Maximum efficiency, stable output in heat, long lifespan, fewer panels and lower installation cost | Lower initial cost, cost-effective for large-scale budget-sensitive projects |

| Key Drawbacks | Higher initial investment | Lower efficiency, requires more space, larger efficiency loss in hot climates |

Monocrystalline solar panels are built with a single and continuous silicon crystal, which provides smooth, dark, and uniform surface. It can maximize the absorption of sunlight and boosts their efficiency. Because of their single crystal and high purity silicon structure, these panels convert sunlight into electricity more efficiently than the other panel types. So they can be a smart choice for projects where space is limited or where maximizing energy output is really important.

The ability to deliver high efficiency, durability, and stable performance makes JA Solar’s monocrystalline panels different in various climates. With modern production techniques, JA Solar panels produce more power and lose less energy inside the cells. Some models have extra features like better back designs, which just help performance but don’t change the main type of the panel and its characteristics..

Most businesses and large scale projects (commercial and industrial) prefer JA Solar’s monocrystalline modules to deliver steady power and last long over the time.

In practice, the JA Solar monocrystalline efficiency typically reaches 20–23%, so developers can install fewer panels but still meet energy needs. This matters significantly for business customers designing rooftops in Sharjah, distribution centers in Baghdad, or ground-mounted systems where surface area and project economics must be optimized.

These panels also hold up well under harsh environments; Their efficiency decreases less in high temperature, allowing for more stable energy during the hottest days of the Gulf region in summers. Additionally, their improved low-light responsiveness helps sustain steady production during early mornings, late afternoons, or hazy conditions, keeping energy generation more stable throughout the day

Polycrystalline that is usually known as multicrystalline panels built from several multiple silicon pieces melted together, While their surface isn’t as smooth, they are more affordable. The manufacturing process is simpler and cheaper, which often means a lower cost per watt. This can be a really big advantage for bulk buyers who think about price and scale.

The JA Solar polycrystalline performance provides a balance of affordability and reliable energy output. While their efficiency tends to be lower, often in the range of 15–18% according to typical industry benchmarks, they still produce reliable power. For large scale procurement or budget sensitive projects, these panels can offer very good value.

However, in very hot climates, polycrystalline performance can dip more than monocrystalline, because their temperature coefficient is often less favorable. That means on scorching summer days in Baghdad or Basra, some of the expected output drop may be larger. Also, to match the same power output, you may need more of these modules, which increases space or mounting structure costs.

Globally, high efficiency technologies are rapidly gaining ground, but polycrystalline panels haven’t disappeared. For certain markets, especially where initial capital cost is a bigger constraint than long term efficiency, polycrystalline remains relevant. Polycrystalline panels can make good business sense for regions with low labor or land expenses, or when contractors focusing on large volume deals.

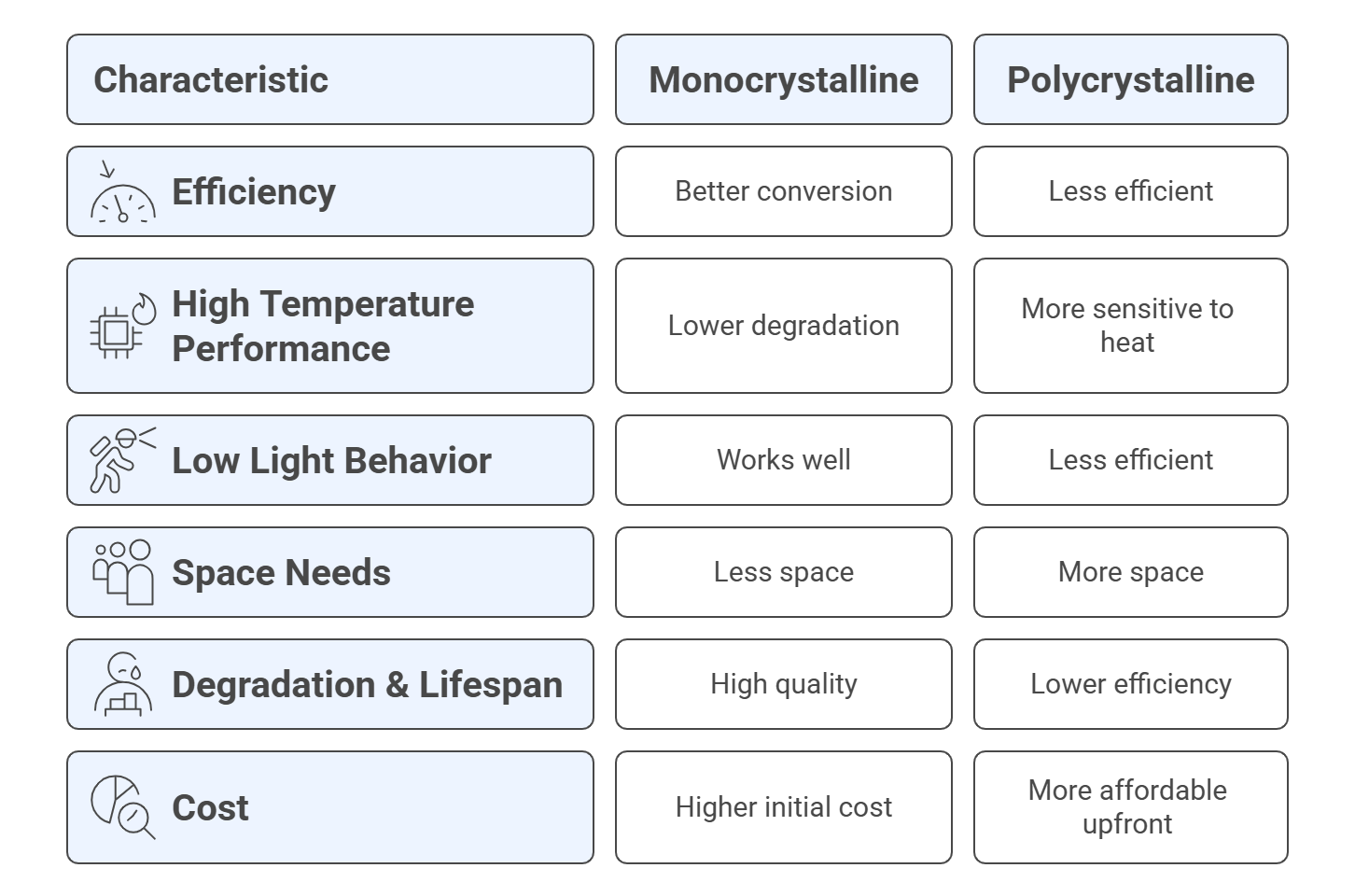

In order to make a smart decision, especially for buying JA Solar products, it’s important to understand exactly how these two panels differ across multiple aspects. Now look at them:

Before making bulk purchasing decisions, most contractors and factory owners want a clear side by side comparison. Here is a detailed JA Solar panel comparison to provide an overview of the most important differences:

|

Feature |

JA Solar Monocrystalline (Mono PERC) |

JA Solar Polycrystalline |

|

Efficiency Range |

About 20%–22% | About 15%–18% |

|

Temperature Coefficient |

Better performance in high temperatures |

Weaker in high temperatures |

|

Low-Light Performance |

Excellent (morning, evening, cloudy days) |

Moderate |

|

Degradation Rate |

Lower (about 0.45% per year) |

Higher (about 0.55%–0.6% every year) |

|

Product Warranty |

12–15 years |

10–12 years |

|

Performance Warranty |

25–30 years |

Up to 25 years |

|

Power Density |

Higher |

Medium |

|

Ideal Climate |

Hot regions, variable sunlight |

Mild to moderate climates |

|

Upfront Cost |

Higher |

Lower |

| LCOE (Cost per kWh) | Lower in the long run |

Potentially higher long term |

Every project has different expectations, budget limits, land size, climate conditions, and required lifetime output. Below is a straightforward guide for choosing the right panel type based on your conditions across Iraq, UAE.

We recommend you to use JA Solar Monocrystallin, because the main goal of these projects is high energy production and strong return on investment. So Mono can delivers:

This is why most big solar projects developers choose monocrystalline panels as their standard

We recommend you to use JA Solar Monocrystallin, because commercial rooftops such as factory need:

By choosing JA Solar Monocrystallin, businesses achieve economic advantages over the system’s lifetime.

We recommend you to use JA Solar Monocrystalline, because homes and villas usually have small roof space. Higher efficiency = higher daily yield with fewer panels. as their higher efficiency allows you to generate more energy every day and use fewer panels.

We recommend you to use JA Solar Polycrystalline, especially for some projects where keeping initial costs low is essential, including municipal installations or large government tenders, as polycrystalline panels remain a suitable and competitive option.

Choosing between JA Solar monocrystalline and polycrystalline should always involve a financial evaluation. We compare these two technologies with each other in practice:

Because monocrystalline produces more power from per panel, so you need fewer panels and lower structure cost. By choosing this option you will reduce cabling and labor as well. This often minimizes the difference in final pricing.

Mono polycrystalline panels can produce 5 to 12% more energy every year. It depends on the climate and the way of installation from different angles.

You will achieve 1 to 2 years faster ROI by choosing monocrystalline systems. The climate has an impact in hot weather and dusty areas where PERC cells work significantly better. So when it comes to serious industrial projects, Mono PERC often becomes the wiser choice for investment.

Extreme heat, frequent dust exposure, and intense UV radiation convert the Middle East to one of the harshest operating environments for solar panels over the world. So selecting panels is important in countries like the UAE, Iraq, Saudi Arabia.

Mono panels manage the heat more efficiently and keep higher output during summer temperatures all over the region

Dust can reduce sunlight effectiveness. The design of Mono PERC cells helps recover more photons during dusty mornings, cloudy weather and winter seasons with weaker sun exposure.

The same structure of monocrystalline cells gives better long term resistance to UV degradation. This is why Mono PERC has become the preferred choice in countries like UAE, Saudi Arabia, Iraq.

For buyers comparing brands, many evaluate JA Solar modules alongside products from major manufacturers like Trina Solar Company when choosing the best balance of efficiency, durability, and price.

Here you can see a practical checklist for contractors, and investors to evaluate JA Solar monocrystalline vs polycrystalline:

|

Best choice |

If your priority is… |

|

Monocrystalline |

Maximum output from limited space |

|

Polycrystalline |

Lowest upfront system cost |

|

Mono PERC |

Best performance in hot climates |

|

Polycrystalline |

Large government or budget-limited tenders |

|

Monocrystalline |

Best long-term ROI |

| Monocrystalline PERC |

The latest and most stable JA Solar technology |

This approach reduces uncertainty and guarantees more reliable system performance.

Passolar works with bulk buyers who need guaranteed performance, long term financial returns, easy bulk ordering, fast international shipping and valid JA Solar certificates and warranty.

Based on real project data and a careful JA Solar monocrystalline vs polycrystalline evaluation, Pas solar generally recommends JA Solar Monocrystalline PERC for serious installations because they offer higher efficiency and better performance, strong compatibility with modern hybrid and on grid inverters, reduced installation cost because of higher power density, more predictable energy production for 25+ years and lower operational losses in hot climates. For industrial buyers, Monocrystalline repeatedly shows itself as the more reliable and financially rewarding choice.

PAS SOLAR is a Distributer of solar equipment based in UAE. Composed of a team of professionals with the goal to provide customers with the latest Tier 1 Solar system in the region.

"*" indicates required fields